How can Warehouse Management Software help the manufacturing industry?

Warehouse Management Software (WMS) is a tool that helps organizations manage their inventory and distribution processes more efficiently. It is a computerized system that automates the day-to-day operations of a warehouse, from receiving, stocking, and shipping products to tracking and reporting. WMS can help manufacturers keep track of their inventory and make data-driven decisions to improve supply chain performance, optimize warehouse operations, and increase customer satisfaction.

In this article, we will discuss how WMS can be used to benefit manufacturers in their operations. We will look at the features and benefits of WMS, the advantages of using WMS in the manufacturing industry, and common challenges associated with WMS implementation and maintenance. We will also introduce Allmark WMS, which is leading warehouse management software for all sizes of industries.

What is warehouse management software?

Warehouse Management System (WMS) is a software system that helps manufacturers optimize their warehouse operations. It is used to manage the flow of goods, materials, and information between suppliers, warehouses, and customers. WMS provides a single source of truth for inventory and order management, allowing manufacturers to track and manage their stock in real-time. It can also be used to plan and optimize operations for a more effective supply chain.

WMS is an essential tool for manufacturers as it helps them make more informed decisions about their inventory and supply chain operations. It can be used to automate processes such as receiving, stocking, and shipping products, as well as tracking and reporting. WMS also provides visibility into inventory levels, allowing manufacturers to track and manage their stock in real-time.

Benefits of warehouse management software

Using WMS, manufacturers can benefit from improved productivity and efficiency. WMS helps to reduce labor costs by automating processes such as receiving, stocking, and shipping. It also helps to improve accuracy and decrease errors, as WMS can be used to track and manage inventory in real-time. WMS helps to reduce time spent on manual processes, freeing up time for more meaningful tasks.

WMS also provides better visibility into inventory levels, allowing manufacturers to track and manage their stock in real-time. This helps to improve inventory control and accuracy, leading to more efficient operations. WMS can also be used to plan and optimize operations for a more effective supply chain.

Furthermore, WMS helps to improve customer satisfaction by providing faster and more accurate order fulfillment. WMS can be used to track and manage products in real-time, allowing manufacturers to provide customers with more accurate delivery times. This helps to improve customer satisfaction and loyalty, leading to more repeat business.

Warehouse management software features

WMS has many features that can help to improve warehouse operations. These include:

- Automated receiving, stocking, and shipping processes

- Real-time inventory tracking and management

- Automated order processing and tracking

- Barcode scanning and labeling

- Automated replenishment and reordering

- Radio frequency identification (RFID) technology

- Automated packing and shipping

- Reporting and analytics

These features help to improve accuracy and efficiency, allowing manufacturers to better manage their warehouse operations.

Warehouse management software in the manufacturing industry

WMS is an essential tool for the manufacturing industry. It can help manufacturers optimize their warehouse operations and make data-driven decisions to improve supply chain performance. WMS can be used to automate processes such as receiving, stocking, and shipping, as well as tracking and reporting. This helps manufacturers save time, labor, and money, leading to more efficient operations.

Manufacturers can also use WMS to improve inventory control and accuracy. WMS provides visibility into inventory levels in real-time, allowing manufacturers to track and manage their stock more effectively. This helps to reduce errors and improve customer satisfaction, leading to more repeat business.

Advantages of warehouse management software for the manufacturing industry

WMS can provide a range of advantages for the manufacturing industry. These include:

-

Improved accuracy and efficiency

- Reduced labor costs

- Improved inventory control and accuracy

- Improved customer satisfaction

- More efficient supply chain operations

- Reduced errors and improved accuracy

- Automated processes

- Real-time visibility into inventory levels

These advantages can help manufacturers optimize their warehouse operations and make better decisions about their inventory and supply chain performance.

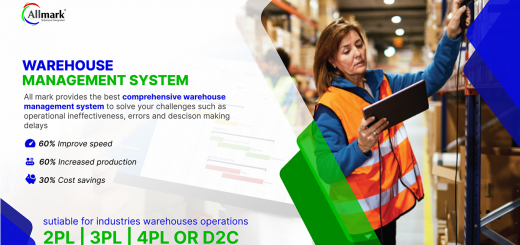

Allmark WMS – Best warehouse management software for all sizes of industries

Allmark-WMS is leading warehouse management software for all sizes of industries. It is a powerful and easy-to-use system that can help manufacturers optimize their warehouse operations and make data-driven decisions to improve supply chain performance.

Allmark WMS includes features such as automated receiving, stocking, and shipping processes, real-time inventory tracking and management, and automated order processing and tracking. It also includes features such as barcode scanning and labeling, automated replenishment and reordering, radio-frequency identification (RFID) technology, automatic packing and shipping, and reporting and analytics.

Allmark WMS is secure and reliable, and it is designed to meet the needs of the manufacturing industry. It is a cost-effective solution that can help manufacturers optimize their warehouse operations and make better decisions about their inventory and supply chain performance.

Conclusion

Warehouse Management Software (WMS) is a powerful tool that can help manufacturers optimize their warehouse operations and make data-driven decisions to improve supply chain performance. It can be used to automate processes such as receiving, stocking, and shipping, as well as tracking and reporting. WMS also provides better visibility into inventory levels, allowing manufacturers to track and manage their stock in real-time.

Allmark WMS is leading warehouse management software for all sizes of industries. It is a powerful and easy-to-use system that can help manufacturers optimize their warehouse operations and make data-driven decisions to improve supply chain performance.

If you are looking for cost-effective warehouse management software for your manufacturing business, Allmark WMS is the right option. Get a free quote today and find out how Allmark WMS can help you optimize your warehouse operations and make data-driven decisions to improve supply chain performance.