Guide to Choosing Best Barcode Labels – Part II

Choosing the right barcode label for production floor is a challenge that many of our clients come up against. In every aspect of product and inventory tracking, barcodes are widely used and becomes a necessity. A barcode or QR code could be seen printed in Paper Label or Polypropylene Stickers and Textile Tags /Labels.

Most common types of label materials are Direct Thermal Paper Label, Thermal Transfer Paper Label and Synthetic Labels.

Direct Thermal Labels are available in Paper and Coated Paper and is self-inked to transfer the print image, while subjected to the heat-transfer of Thermal Print Head (TPH) engine. Paper labels with wet-strength capacity – could become handy in applications where products are exposed to small amounts of water such as storage in refrigeration.

Paper Labels and Synthetic Labels works in combination with Wax/Resin Ribbons. Both Paper and Synthetic labels are of self-adhesive type.

Paper labels

Paper labels are a solid choice for general purpose applications, and most inexpensive for use in applications of shipping labels, inventory labels and work-in-progress (WIP) goods that still need to be tracked for becoming a final product.

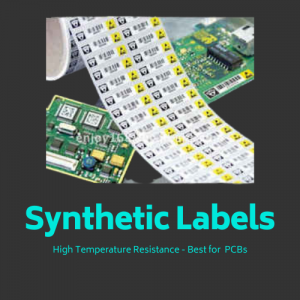

Synthetic labels

Synthetic labels are preferred in applications where durability and resistance to harsh chemical and environmental factors.

Polypropylene – It offers medium mechanical resistance and tend to crease and stretch slightly and is preferred label stock for Barcodes and barcode related contents for use of resistance against oil, water and tear and is slightly expensive than paper labels and offer low-level durability. Pharmaceutical industry uses this label due to the lowest risk of migration that is the substance from the adhesive doesn’t pass through the bottle.

Polyester Labels – Polyester labels are most durable and become a best choice for outdoor and in rugged environments with harsh chemical, water and oil exposure.

Polyethylene Labels – It is less rigid material than polyester and therefore become a great choice for curved surfaces such as bottles and vials.

Polyimide – These are highest performing labels that withstand temperatures in excess of 250 degrees and up to 500 degrees. It is thermally very stable and becomes an ideal choice for electronic PCBs in wave-soldering process which involves direct wave (bottom side) and IR reflow (top-side).

Polyimide labels are used in industries and applications such as;

- Electronic Component Tracking

- Warning and Hazard Labels

- Aerospace

- Automotive

Vinyl Labels – These variants offer tamper-resistant and breaking into small pieces if removal is attempted.

Tamper–Evident Labels – Tamper Evident labels are designed as a print-on-demand option to secure products against warranty-fraud, product tampering and asset theft. Most widely used labels include, one that leave irreversible, visible evidence when the label has been tampered with and the other that is fracturing when removed. Industries use both destructible and non-destructible face-stocks which include paper, vinyl and polyester for reliable use. Tamper Evident Labels feature a range of finishes including white, mirror finish and bright silver to match a variety of design needs.

No Residue category labels will display a message such as “OPEN” and “VOID” on the label and will not leave any residue on the applied surface.

The recommended applications are;

- Destructible Labeling Applications

- Thermal Transfer Labels – Barcode Tracking

- Variable Information Printing (VIP)

- Brand and Instruction Labels

- Warning Labels

- Tamper Indicating

(Food Packing, Parcels through Courier Services and Warranty Void for devices)

- VOID Messaging

Acrylic – Suitable for Long product life-cycle in outdoor applications.

Textile industry prefers Nylon Taffeta Labels that can be printed by thermal transfer. They are washable at 90 0C, 40 minute light stone wash cycle. Also, automobile industries, started to use adhesive taffeta for airbag labels. The service temperature of these labels varies between -40 0C and +115 0C and their minimum application temperature is 10oC.

Tamper-Evident VOID Material Labels

Tamper Evident labels are designed as a print-on-demand option to secure products against warranty-fraud, product tampering and asset theft. Most widely used labels include, one that leave irreversible, visible evidence when the label has been tampered with and the other that is fracturing when removed.

No Residue category labels will display a message such as “OPEN” and “VOID” on the label and will not leave any residue on the applied surface.

- The recommended applications are;

- Destructible Labeling Applications

- Thermal Transfer Labels – Barcode Tracking

- Variable Information Printing (VIP)

- Brand and Instruction Labels

- Warning Labels

- Tamper Indicating

(Food Packing, Parcels through Courier Services and Warranty Void for devices) - VOID Messaging

Well, now that you have come to know the factors surrounding barcode labels.

Allmark look forward to have your feedback and queries to associate with your business requirement.

For any questions, feel free to contact Allmark and write to us at sales@allmark.in or call us at +91 9551658565 and one of our sales team member will be happy to speak to you.