Guide to Choosing Best Barcode Labels Part I

There are many factors to consider when choosing exactly which label is right and best for your business. This guide benefits the reader on six paramount factors that must be considered into choosing the right labels. The barcode is only as reliable as it is printed onto the label stock and remains where it is applied, through the entire product cycle.

There are many factors to consider when choosing exactly which label is right and best for your business. This guide benefits the reader on six paramount factors that must be considered into choosing the right labels. The barcode is only as reliable as it is printed onto the label stock and remains where it is applied, through the entire product cycle.

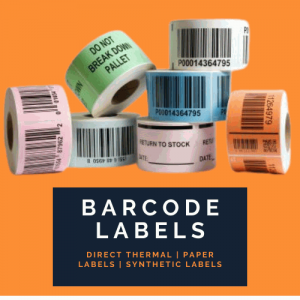

Barcode-Labels-Stickers

Label is also known as a sticker and a cost-effective media for barcode printing, primarily because, it is easy to design (typically cut to your desired size), print and attach. The anatomy of a label consists of face stock, adhesive, release coating and a backing paper.

Label is also known as a sticker and a cost-effective media for barcode printing, primarily because, it is easy to design (typically cut to your desired size), print and attach. The anatomy of a label consists of face stock, adhesive, release coating and a backing paper.

Each business, within the organizations have different barcode label and media needs, for use-case such as Asset Labels, Shipping Labels, Product Labels, Clothing tags, Shelf/Location Tags, and Wristband Labels.

Functional aspects of the label

Both the user and the supplier of Barcode Labels must be answered of a question; What must the label DO? The label industry, dealers and users have well defined and summarized below; The label MUST stay on surface when applied at temperature for time period and during this time period, the label will be exposed to solvents, dust, and other environmental contaminants. Also, the user and supplier must consider, the operating temperature of minimum / maximum (what to what) for (how long). Answering these questions will lead to the selection of right ribbon/label, in connection with adhesive.

Selecting the right and proper media for label printing application requires an understanding about variety of material, adhesive, and size.

# 6 Factors to consider while choosing the best labels and thermal transfer ribbons

- Application Surface Type (Flat, Low Surface Energy, etc.)

- Service Temperature

- Abrasion and Tear Resistance

- Printing Technology to be employed

- Environments Conditions (UV, Humidity, Chemical Resistance, Water Immersion, etc.)

- Lifespan of Barcode and Image Quality

Knowing these six key factors will help avoid the downfalls of choosing the wrong label. This in turn keeps your operational efficiency strong.

- Surface – What your labels will be placed-on plays a big role in how well they can adhere to your product and packaging surface. Some surface materials provide better adhesion than others depending on few factors;

Surface Energy

Lower Energy materials like Polystyrene and nylon may require a stronger adhesive to ensure that your labels will last. High Energy surfaces like, metals and glass are great for adhesion. Adhesive coat may not flow well on rough surfaces and pose some problem, while smooth surfaces offer great adhesion.

- Temperature – It is critically important that the labels adhere successfully during application and also they remain in place during the entire product lifecycle.

- Minimum Application Temperature – It is the lowest temperature recommended during labelling.

- Service Temperature – It is the range of recommended temperature for storing a label that has already been applied to a surface.

Most of the labels support application temperature of +50C conditions. The general service temperature lies within the range of -400C to +800C.

- Abrasion Resistance – Contact and rubbing affects label readability over time. A thermal transfer label with higher resin content provides higher resistance levels.

- Shear Resistance – It refers to the strength of a label adhesive. Generally, low-shear labels have higher initial tack, but are vulnerable to strain. Adhesives with high shear offer lower initial tack and less susceptible to cracking and tearing under stress

- Solvent Resistance – It refers to the reactive quality of adhesive as how well resists to solvents like alcohol, petrochemicals, and the universal solvent – Water.

- Print-Image Quality – Label Material Type (Direct Thermal, Paper, and Synthetic Labels) and Thermal Transfer Ribbon selection is influenced in conjunction with Printing technology employed and Print Speeds.

- Environments Conditions – Chemical – When a label is exposed to moderate to extreme chemicals such as acetone or oil, a thermal transfer label with high durability resin will prevent print image deterioration. Indoor/Outdoor – Products exposed to outdoor elements such as rain and sun should use a thermal transfer synthetic material. This material provides the durability needed to survive tough environmental factors.

- Lifespan of the Print Image – Print Method – A label with a longer lifespan is more likely to be exposed to chemicals, moisture, and abrasion, whereas a shorter lifespan will not require a highly durable label.

Direct Thermal Printing Method

The life span of the print quality directly depends on the print method or technology chosen to print. Direct Thermal media does not use any kind of ink or ribbon to create the print image on the label, since the label media is coated with heat-sensitive layer that turn into image. The shelf-life of direct thermal media is short (< 1year), when not exposed to direct sunlight or abrasion. For shipping label, direct thermal label is a cost-effective option.

Thermal Transfer Printing Method

The thermal transfer media is resistant to heat and moisture and abrasion. This method of printing involves two media – label and ribbon and making the print quality most durable with a long shelf-life of more than 1 year.

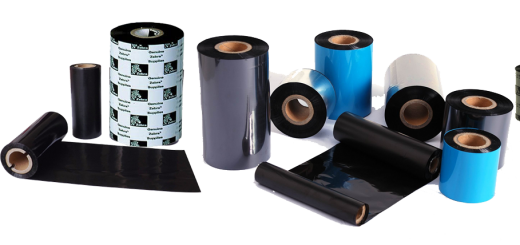

Thermal Transfer Ribbon Types

Each label material will require different ribbons (ink) and choosing the right ribbon ensures to get clearest and lasting print image.

Tags

Clothing-Tag is one of the product identification methods with barcode and other information in apparel stores that does not have adhesive and is thicker than the paper label. Tags fit into use-case scenario where the surface is not smooth and where the label to be removed from the product without leaving adhesive residue.

Wristbands

Wrist bands are a very specialized option for barcoding but also the best fit for the application of tracking patient in Healthcare eco-system and events where people of mass gathering happen.

Good details sharex

Thank you for your feedback and time to appreciate us.