How to choose the best type of Thermal Transfer Ribbon?

In recent times, you would have read in our blog about the tips and guides to choose the barcode labels and selection of barcode label printer for your different needs.

Whether it is for use in the warehouse or in the production to track inventory, the thermal transfer ribbon selection is important to achieve best print images that are legible and durable.

Knowing the details and understanding types of thermal transfer ribbon is important to as equal as the selection of labels and label printers.

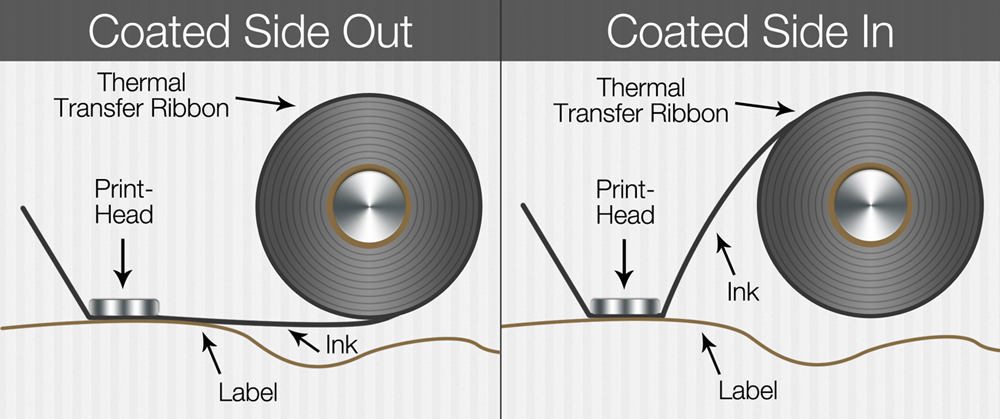

Thermal Transfer Ribbon is a carbon-based ribbon that chemically transfers the print image when in reaction to the heat from Thermal Print Head of a Label Printer. The ribbon roll is clear plastic film that is coated on one side. The coating is either Full Wax or Full Resin or a combination of both.

Functional Aspect:

In the printing process, the uncoated side of the thermal transfer ribbon passes over the print-head to undergo the heating and a resultant effect, the carbon ink is transferred to the label stock, to creating high-quality images.

Types of Thermal Transfer Printers

There are two types of Thermal Transfer Printers, one is of FLAT-HEAD and the other is NEAR-EDGE. At times, a person tends to use near-edge ribbon in a flat-head printer and comes up with poor quality images. Then, technician or trained users at customer’s premise try to overcome the problem by adjusting the print-head pressure. This practice will be the source for premature wear and damage of the Print-head and make a dent in the operation cost. So, it is wise to take caution to buy the right ribbon for the type of printer.

Types of Thermal Transfer Ribbons

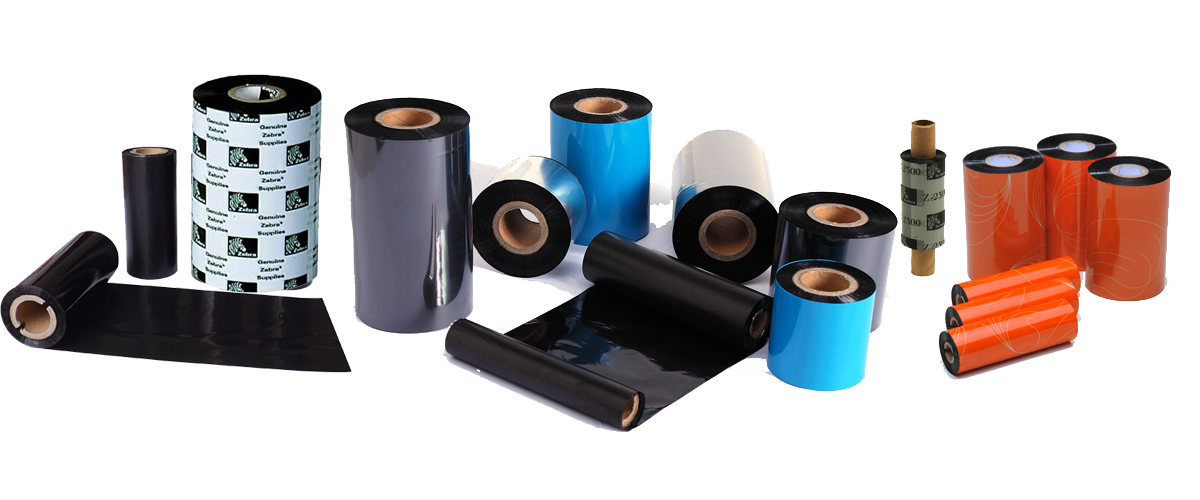

There are three important ingredients that define the type of the ribbon, which are Color, Wax and Resin. The composition of Wax and Resin makes the type and relevance to the application. Wax is to stabilize the carbon color and the Resin is to define the durability of the print image. The composition is main ingredient makes the variant as – Full Wax, Wax/Resin, and Full Resin Ribbons.

All these ribbons come with two categories;

1. Coated Side Out (CSO) – Used in Zebra, TSC, and Godex Thermal Transfer Printers and

2. Coated Side In (CSI) – Used in Sato and Datamax Printers.

The picture offers self-explanatory understanding of these categories.

Full Wax Ribbons – Most Commonly used ribbon

This consists of a layer of wax-based ink and needs lower temperature to melt when in comparison to the resin-composition-based ribbons. The absence of resin means, the wax-ribbons are susceptible to scratching, smudging, heat, cold, moisture and chemicals. The wax ribbons are low cost and economic option, but the economy comes with the compromise on durability.

This consists of a layer of wax-based ink and needs lower temperature to melt when in comparison to the resin-composition-based ribbons. The absence of resin means, the wax-ribbons are susceptible to scratching, smudging, heat, cold, moisture and chemicals. The wax ribbons are low cost and economic option, but the economy comes with the compromise on durability.

Wax Ribbon is recommended for coated and uncoated paper labels, Gloss Paper Labels and Tags. These ribbons are most widely used for;

• Shipping Labels

• Retail Labels

• Product ID

• Parts Packaging

• Shelf Labelling

Wax/Resin Ribbons – Suitable for both paper and synthetic labels and offer moderately durable

As the name represents, it is a mixture of wax and resin in certain composition and formulation. The resin ingredient in the ribbon requires higher temperature to melt compared to full-wax ribbons. This type of ribbons are well preferred for printing quality image at a high speed on a variety of surfaces, while offering resistance to scratches, smudges and chemicals. A longer durability of print image does come at a cost, and Wax/Resin Ribbons are the ideal choice.

As the name represents, it is a mixture of wax and resin in certain composition and formulation. The resin ingredient in the ribbon requires higher temperature to melt compared to full-wax ribbons. This type of ribbons are well preferred for printing quality image at a high speed on a variety of surfaces, while offering resistance to scratches, smudges and chemicals. A longer durability of print image does come at a cost, and Wax/Resin Ribbons are the ideal choice.

Wax-Resin Ribbon is recommended for coated paper label, Polyethylene, Polypropylene, and polyolefin labels. These ribbons are most widely used for;

• Compliance labels

• Retail Tags

• Bin Labels

• Pharmaceutical Labels

Full Resin Ribbons – For extreme and harsh conditions

Resin ribbon contains of more percentage of resin in the ink coating than the wax and wax-resin ribbons and therefore requires high heat-setting of print-head. The print image out of the use of resin ribbon provides image that is durable and is extremely resistant to abrasion, heat and chemicals. The resin ribbon is expensive when compared to wax and wax-resin ribbons, and offers highest quality.

Resin ribbon contains of more percentage of resin in the ink coating than the wax and wax-resin ribbons and therefore requires high heat-setting of print-head. The print image out of the use of resin ribbon provides image that is durable and is extremely resistant to abrasion, heat and chemicals. The resin ribbon is expensive when compared to wax and wax-resin ribbons, and offers highest quality.

Full Resin Ribbon is recommended for coated paper label, Polyethylene, Polypropylene, and Polyolefin labels. These ribbons are most widely used for;

• UL/CSA Labeling

• Outdoor Applications

• Automotive Labeling

• Electronic PCB labeling

It is now to little more about other physical parameters of the ribbon that fits into the type and make of the printer in use.

Ribbon Width

Select ribbon width which is closest to that of a label width to be printed. As an example, when printing 50mm of label width, then you should choose 60mm ribbon width, instead of 110mm width. This avoids the wastage of ribbon and saves money.

Ribbon Length

Desktop printers such as Zebra GC420 and ZD220 can accommodate shorter ribbon length (74 Mtrs) only. Printers such as Zebra GT800, ZD230, TSC TE 244, TSC TTP 244 PRO, Godex G500 and EZ1100 Plus models would accommodate 300 Meters, length of ribbon. Certain Industrial Printer would support 450 meters of length.

Core Size

Smaller Printer supports 0.5 inch core, while other printers support 1 inch core size.