The difference between thermal transfer and direct thermal Printing

We place before the user, the information that you need to know, for perfect label quality and printing. This piece of article helps you all, to know most of the key aspects about direct thermal and thermal transfer printing. Both Thermal Printers and Thermal Transfer Printers are capable to produce barcode labels which are high-quality images with excellent edge definition and that the barcode scanners capture data successfully.

We place before the user, the information that you need to know, for perfect label quality and printing. This piece of article helps you all, to know most of the key aspects about direct thermal and thermal transfer printing. Both Thermal Printers and Thermal Transfer Printers are capable to produce barcode labels which are high-quality images with excellent edge definition and that the barcode scanners capture data successfully.

These printers can print both linear and two-dimensional barcodes such as data-matrix or QR Codes, text and graphics with either thermal printing method.

Let us look at the similarities at first:

Both printing technologies involve the key component, thermal print head that applies heat to the surface media material in contact. The general term thermal printer may be used for direct thermal label printers as well as for thermal transfer printers. Their printing resolution is specified in dots per inch (dpi). It is usually 203, 300 or 600 dpi. The higher the number of dpi and that relates to higher print resolution and print quality.

The actual difference between the two methods is in the surface that is heated by the thermal printhead. Thermal transfer printing uses a wax- or resin-based ribbon that comes in contact with the printhead, when heated, it transfers ink onto the label.

Conversely, Direct thermal printing heat directly the labels (heat-sensitive) that is in direct contact with the printhead and turns the label with the print image.

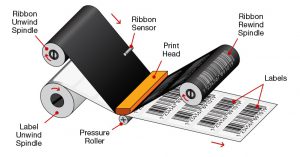

How does a thermal transfer printer work?

In thermal transfer printing, the paper label which passes between heat transferring thermal head and the wax or wax resin ribbon. The printhead which is an heating element that apply punctual heat to the passing ribbon, thus causing it to melt onto the label and form the print image.

In thermal transfer printing, the paper label which passes between heat transferring thermal head and the wax or wax resin ribbon. The printhead which is an heating element that apply punctual heat to the passing ribbon, thus causing it to melt onto the label and form the print image.

Each industry and within the organization, each use-case needs different label stock (label and adhesive) and ribbon (wax or wax resin or resin) in order to achieve optimum print quality and durability. One must choose the label and ribbon media with respect to printing speed of the printer.

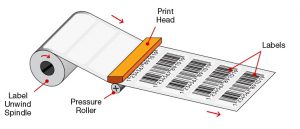

How does a direct thermal label printer work?

The label with a heat-sensitive coating comes in direct contact with the heating element, thermal printhead which apply punctual heat to the passing label.

The label with a heat-sensitive coating comes in direct contact with the heating element, thermal printhead which apply punctual heat to the passing label.

The heat and chemical reaction causes the label to change colour from white to black and create the image.

A comparison table below supports the user to choose the printing method and printer.

| Thermal transfer | Direct thermal | |

| Print quality | Supreme readability and Scannability | Good readability and Scannability |

| Print durability | Long-life image stability | Particularly and extremely sensitive to heat, light and other environmental conditions (label will darken when overexposed and suffer Scannability) |

| Colour printing | Single Colour Printing with coloured ribbon | Only black and white |

| Print head life | Higher life due to the mechanism that the ribbon (with back-coating) acts as buffer between print head and label material which reduces static and friction. | As the print head is in direct contact with abrasive labels which presents wear-out. This necessitates the printhead replacement and increases the cost. |

| Printer configuration and maintenance | · The printer downtime is more due to ribbon changes, parts cleaning and adjustments.

· Can print on variety of label media such as polyester and synthetic. |

· Simple to operate, because no ribbon required and less moving parts due to absence of ribbon holding and rotation modules. Less maintenance cost. |

| Media selection and cost | · Generally the media cost is lower and needs a careful choice of media depending the use-case. | · Higher cost for direct thermal labels |

| Typical applications | Product and packaging labels, GHS labels, asset tags | Shipping labels, receipts, tickets |

Conclusion

A thermal transfer printing supports durable and high-resolution images, and greatly in demand for traceability applications and where labels are exposed to harsh conditions such as chemicals, sunlight and open-area exposures

A short shelf-life labelling application goes well with direct thermal printing and makes a business sense with simple and cost-effective choice.

We welcome your call and willing to offer our expertise, if you still need more to know.

You can call us and contact our team at +91 9551658565 / +91 9551658515 / +91 9551658525 or write to us at sales@allmark.in

Allmark offers end-to-end barcoding solutions with the world’s most popular printer brands such as Zebra, Honeywell, TSC, and Datamax. We also offer customised software solutions for label printing and to traceability of products in your warehouse and at your manufacturing plants.

1 Response

[…] Thermal Transfer Printing Method […]