Direct and Thermal Transfer Printers – Pros and Cons

Advantages and Disadvantages – Direct and Thermal Transfer Printers

Direct Thermal Printers are designed simple, that means they come with uncomplicated design and reliable to operate. The cost of operating, thermal printers for printing barcode labels is often affordable, because it involves only two components that are the printer and the label.

The thermal print images may fade over time and or with exposure to heat and light. This technology is best used in applications and limited to where the product is not in circulation for long period of time.

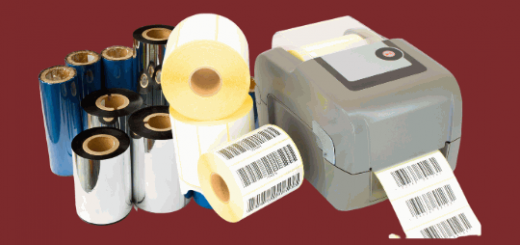

Conversely, the Thermal transfer Printer technology melts the ink coated over the ribbon and transfer to the label, which is absorbed by the paper label. This makes the print images more durable for longer length of time. Thermal transfer printers can support with a wider variety of label materials, including paper, and polypropylenes.

The Most and Best Applications for Thermal Printers

• shipping labels

• receipt tickets

• inventory identification labels

• pick lists

• Visitor Labels

• Event Tickets

The Widely used Applications for Thermal Transfer Printers

Thermal transfer printing works well for applications where readability is required over a longer time.

• Auto Parts Identification Label

• Work-in-Progress Tracking Label

• Patient Wrist band

• Material Compliance Label

• Warranty Identification or Product Tracking Serial Number Tags

Industries that have harsh conditions, chemicals, and sterilization, sunlight and temperature extremes prefer to use Thermal Transfer Label Printers for printing quality images and barcodes. It is important to consider the print speed while choosing the print media such as thermal ribbon and the label material for consistently high quality images.

Allmark can help you determine which technology will be best for your application and ensure you have the right materials and compatible inks for your labels. Write to us at sales@allmark.in or call us at +91 955 165 8565 for more information.

2 Responses

[…] thermal transfer media is resistant to heat and moisture and abrasion. This method of printing involves two media […]

[…] Direct Thermal Labels are available in Paper and Coated Paper and is self-inked to transfer the print image, while subjected to the heat-transfer of Thermal Print Head (TPH) engine. Paper labels with wet-strength capacity – could become handy in applications where products are exposed to small amounts of water such as storage in refrigeration. […]